Heat Pump Failure – Causes, Diagnosis & Repair

When dealing with Heat Pump Failure, the loss of heating or cooling performance in a heat pump system. Also known as heat pump breakdown, it usually points to trouble in core parts like the compressor, a refrigerant circuit issue, or a faulty thermostat. Understanding these components helps you decide whether a quick fix will do or a professional call is needed.

What Triggers a Heat Pump to Stop Working?

Heat pump failure often starts with compressor wear. The compressor is the heart of the system; if its internal valves stick or the motor burns out, the pump can’t move refrigerant. A second frequent culprit is a refrigerant leak. Low refrigerant pressure means the pump can’t absorb heat, leading to weak output or total shutdown. Third, thermostat miscalibration sends wrong signals, making the unit think the desired temperature is already reached. Lastly, poor airflow caused by dirty filters or blocked ducts forces the system to overheat, which triggers safety shut‑offs.

These causes aren’t isolated. A clogged filter can raise the coil temperature, stressing the compressor and accelerating refrigerant loss. That chain reaction explains why several symptoms appear together: reduced heating, strange noises, and error codes on the control board. Recognizing the pattern saves time and avoids unnecessary part replacements.

Diagnosing a heat pump involves checking the broader HVAC system as well. First, verify the electrical supply—tripped breakers or loose connections are simple fixes that often get missed. Next, run a pressure test on the refrigerant line; a certified technician can pinpoint leaks quickly. Finally, inspect the thermostat settings and sensor placement. Aligning these steps with the system’s manual ensures you cover the most common failure points before calling in a specialist.

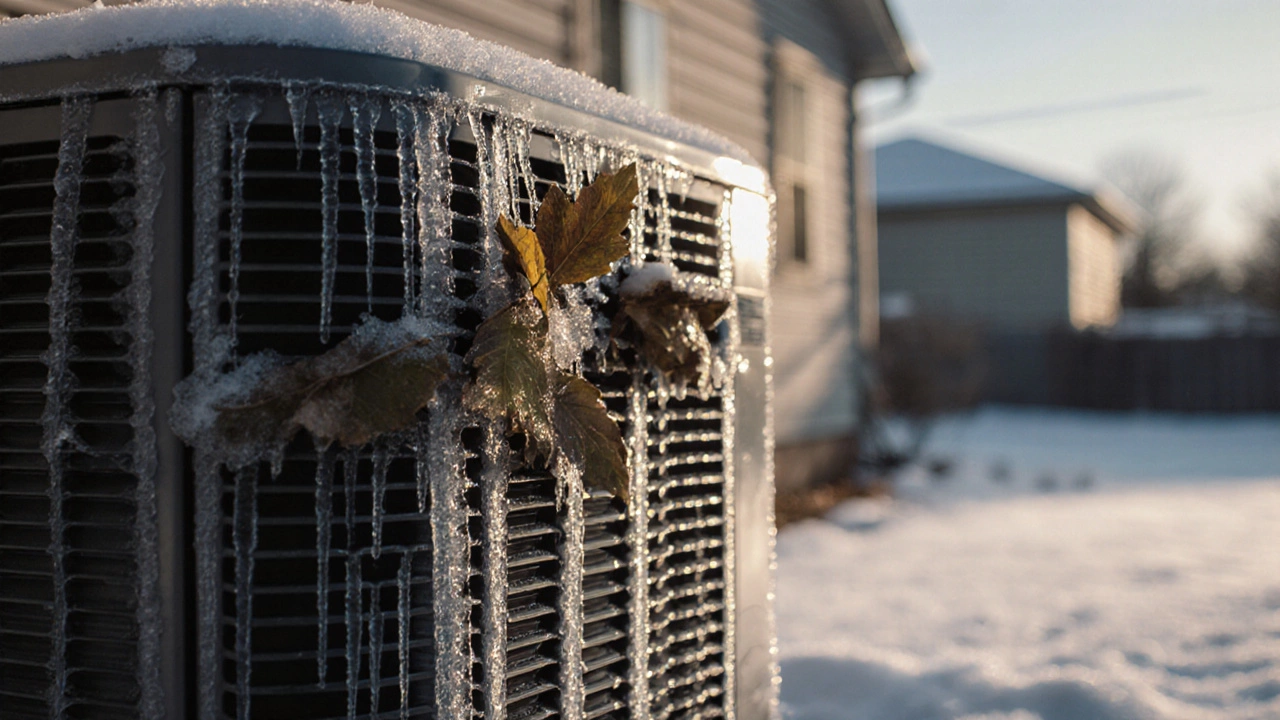

If you’re comfortable with basic DIY, start with the easy wins. Replace or clean the air filter, clear any debris around the outdoor unit, and reset the system using the manufacturer’s reset procedure. These actions can restore normal operation in up to 30 % of failure cases. For anything beyond that—like compressor humming without start, visible frost on the coils, or persistent error codes—it's wise to involve a qualified repair service.

When you do call a pro, they’ll typically assess the following attributes: compressor health (measured in horsepower and operating temperature), refrigerant charge level (ounces of R‑410A or R‑22), and thermostat accuracy (usually within ±1 °C). Knowing these parameters helps you understand the repair quote and decide if replacement makes financial sense.

Heat pump failure doesn’t have to mean a new system. Regular maintenance, such as seasonal inspections, coil cleaning, and refrigerant checks, can extend your unit’s life well beyond the average 15‑year expectancy. Proactive care also reduces the risk of sudden breakdowns during extreme weather, which is when you feel the loss of heating or cooling most acutely.

Below you’ll find a collection of articles that dive deeper into each of these topics—compressor troubleshooting, refrigerant handling, thermostat calibration, and HVAC system upkeep. Whether you’re a homeowner looking for quick fixes or someone considering a full service, the posts will give you clear steps and realistic cost expectations.

Most Common Heat Pump Problem and How to Fix It

- Alden Wilder

- Oct 8 2025

- 0 Comments

Learn why ice buildup on the outdoor coil is the most common heat pump problem, how to diagnose it, and when to DIY or call a pro.

View More