Boiler Maintenance Tracker

Monthly Tasks

Quick checks to do every month for immediate safety and performance.

Quarterly Tasks

Deeper inspections every 3 months for critical safety components.

Maintenance Schedule

Progress Overview

Overall Progress

0%

Tips for Success

- Set calendar reminders for key dates

- Keep a maintenance log

- Install a CO detector near the boiler

- Budget for annual professional service

Keeping your heating system reliable all winter starts with one simple habit: regular boiler maintenance. A well‑tended boiler not only stays warm when you need it, it also saves energy, cuts repair bills, and lasts longer. Below is a no‑fluff guide that walks you through the exact tasks, timing, and tools you need so your boiler runs like a champ.

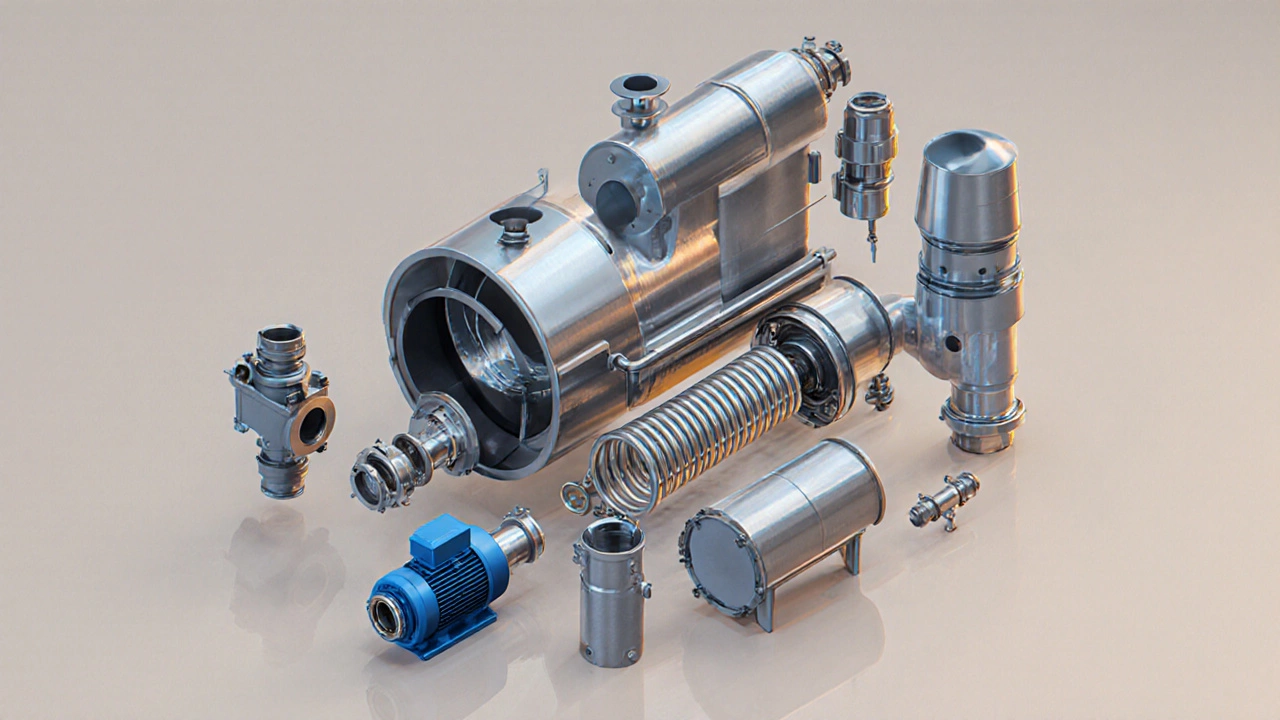

What a Boiler Actually Is

Boiler is a closed‑loop heating device that heats water or produces steam to distribute heat throughout a building. It typically consists of a combustion chamber, heat exchanger, circulation pump, and a suite of safety components. Understanding its parts makes it easier to spot when something’s off.

Key Components to Watch

Here are the main pieces you’ll be checking during routine care. Each paragraph introduces the component with microdata so search engines can link the facts correctly.

- Pressure relief valve is a safety valve that releases excess pressure to prevent boiler explosion.

- Heat exchanger is a metal coil that transfers heat from burned gas to the water circulating in the system.

- Combustion chamber is a sealed area where fuel mixes with air and ignites.

- Thermostat is a control device that tells the boiler when to turn on or off based on room temperature.

- Expansion tank is a small vessel that absorbs water expansion caused by heating.

- Flue pipe is a vent that carries exhaust gases safely out of the house.

- Circulation pump is a motor that moves hot water through radiators or under‑floor pipes.

- Burner is a device that mixes fuel and air and creates the flame that heats the water.

Why Regular Maintenance Matters

Skipping a yearly check can lead to three common problems: reduced efficiency (up to 15% loss), carbon monoxide leaks, and component failure. In Vancouver’s damp climate, corrosion is a hidden enemy, especially for the heat exchanger and flue. A quick glance each month catches early warning signs before they become costly repairs.

Monthly Quick‑Check Routine (5‑Minute Tasks)

- Inspect the pressure gauge. It should sit between 1 and 1.5 bar when the system is cold. Anything outside this range hints at a leak or faulty expansion tank.

- Listen for unusual noises from the circulation pump or burner. Rattling may indicate a loose mounting or worn bearings.

- Check visible pipe joints for moisture or rust. Small drips can become big floods.

- Test the thermostat by raising the temperature setting a few degrees. The boiler should fire up within a minute.

Quarterly Care (Every 3Months)

Take a deeper look at safety valves and exhaust pathways.

- Open the pressure relief valve briefly to ensure it releases water without obstruction.

- Examine the flue pipe for soot buildup or corrosion. A thin white coating may mean condensation is pooling, which can erode metal over time.

- Wipe down the burner visible area with a soft brush. Dust can affect flame quality and raise emissions.

Annual Professional Service (Once a Year)

Even a diligent DIYer should call in a certified technician at least once per year. They’ll perform diagnostics that require specialized tools, such as:

- Combustion analysis to verify the fuel‑air mix is within safe limits (CO levels below 30ppm).

- Heat‑exchanger inspection with a borescope to spot cracks or scaling.

- Pressure‑test of the expansion tank and sealed system for leaks.

- Full cleaning of the flue and burner assembly.

Most service contracts include a safety check, cleaning, and a performance report that tells you the exact efficiency percentage.

Seasonal Prep: Spring and Fall

Before the heating season starts, and after it ends, run a short start‑up and shut‑down cycle.

- Turn the thermostat to the highest setting and watch for a steady flame and stable pressure.

- After a few hours, lower the thermostat to turn the boiler off. Verify that the water cools and the pressure drops back to the standby range.

This helps flush out any sediment that settled during the off‑season and confirms the system’s readiness.

Maintenance Checklist Table

| Task | Frequency | Tools Needed | Typical Time |

|---|---|---|---|

| Check pressure gauge | Monthly | None | 2min |

| Listen for abnormal noises | Monthly | None | 3min |

| Inspect pressure relief valve | Quarterly | Wrench | 5min |

| Clean burner and flue | Quarterly | Soft brush, vacuum | 15min |

| Full professional service | Yearly | Technician equipment | 2‑3hrs |

| Seasonal start‑up/shut‑down test | Twice a year | Thermostat | 10min |

Common Pitfalls and How to Avoid Them

- Ignoring low pressure. If the gauge consistently reads below 1bar, the expansion tank may be water‑logged. Re‑pressurize or replace the tank.

- Skipping the flue check. A blocked flue can cause carbon monoxide buildup. Install a CO detector near the boiler as a safety net.

- Using harsh chemicals. Acidic cleaners can corrode the heat exchanger. Stick to mild detergents and a soft brush.

- Over‑tightening valves. Applying too much torque on the pressure relief valve can strip threads and cause leaks.

When to Call a Pro

Even with a solid DIY routine, some warning signs demand a licensed technician:

- Persistent low pressure despite topping up.

- Unusual pilot light behavior (flickering, sputtering).

- Any smell of gas or carbon monoxide.

- Water stains around the boiler base, indicating a hidden leak.

In British Columbia, the Technical Safety BC requires a certified inspector for any gas‑related work, so keep that regulation in mind.

Bottom‑Line Checklist for Busy Homeowners

- Mark your calendar: monthly pressure check, quarterly valve/flare‑up clean, annual service appointment.

- Keep a simple log (paper or app) noting dates, pressure readings, and any odd noises.

- Install a carbon‑monoxide alarm near the boiler and test it monthly.

- Budget 1‑2% of the boiler’s purchase price each year for maintenance and parts.

Follow these steps and you’ll enjoy warm rooms, lower bills, and peace of mind throughout the chilly Vancouver winters.

Frequently Asked Questions

How often should I refill the boiler water?

Boilers are closed systems; you normally only add water when the pressure gauge drops below the recommended range (1‑1.5bar). After topping up, bleed any air from radiators and re‑check the pressure. If you find yourself refilling more than twice a year, there’s likely a leak.

Can I clean the heat exchanger myself?

A light surface clean with a soft brush is okay, but scaling inside the exchanger requires chemical descaling by a professional. Improper cleaning can damage the fins and reduce efficiency.

What does a flashing red light on the boiler mean?

A flashing red light usually indicates a fault code. Check the manual for the exact meaning-common reasons are low pressure, ignition failure, or a blocked flue. Reset the boiler and, if the light persists, call a technician.

Is it safe to use a boiler during a power outage?

Most modern boilers need electricity for pumps and controls, so they stop when the grid goes down. If you have a backup generator, ensure it’s sized to handle the boiler’s startup surge (usually 2‑3kW).

Why does my boiler make a hissing sound?

A mild hissing can be normal steam release, but a loud, continuous hiss often points to a leaking pressure relief valve or a failing gasket. Inspect the valve and replace if needed.